Blog

The lifespan of safety flooring systems and how Polysoft test it

When any new product or system is developed, manufacturer must set the guarantees that will be offered to the market. They must go beyond the legal requirements and therefore the duration of its lifespan must be estimated through accelerated aging tests, environmental tests, pilot projects in extreme conditions, etc. We are going to talk a little bit about the main system used for flooring products today.

One of the most widely used test techniques is accelerated weathering or aging through UV lamps and comparison of the final colour with respect to a colour scale. This technique was established at the beginning of the textile industry but has been adopted in all kinds of industries as a measure of the stability of colours and dyes. The highest value on the scale indicates the best colour stability and therefore the longest shelf-life expectancy.

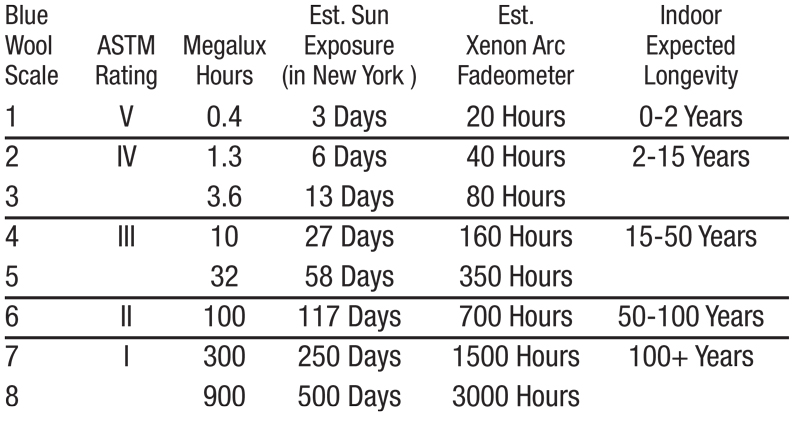

This Blue Wool scale is used also by manufacturers of paints for artists in the ASTM D5067 Standard, you can see the equivalent estimated Sun exposure and Indoor expected longevity for a class number in the scale.

PolySoft products have been subjected to this test by exposure to an Atlas Suntest XLS system for 3 months. Assays were performed at Seascope Laboratories Pty Ltd. In Victoria (Australia). The results reached Class 8 of the Blue Wool scale, which is the highest possible value. This Atlas Suntest is based on a Xenon filtered lamp. The chamber offers a horizontal test plane that is particularly useful for testing three-dimensional samples. Light resistance tests aim to test a material solely under solar radiation and temperature. Water immersion or moisture by spraying can be added to the test chamber for full weathering.

Normally two identical dye 8mm samples of various Polysoft colours, bound by 10% aliphatic polyurethane binder are created. One is placed in the dark as the control and the other is placed in the equivalent exposure of sunlight for a 3-month period. A standard bluewool textile fading test card is also placed in the same light conditions as the sample under test.

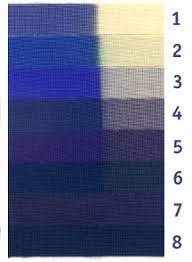

Blue wool scale by JARP

The amount of fading of the sample is then assessed by comparison to the original colour.

A rating between 0 and 8 is awarded by identifying which one of the eight strips on the blue wool standard card has faded on the same extent as the sample under test.

Zero denotes extremely poor colour fastness while a rating of eight is deemed not to have altered from the original and thus credited as being lightfast and permanent. Scale is used to predict the suitability for a given end use; typically, apparel would need a minimum of grade 4 whilst furnishings would require a grade 6. This system is used in the ISO 105 B series of tests.

The method of comparison between the sample and a test strip enables accelerated testing to be carried out under intense artificial illumination.

In addition to the colour change performance, physical characteristics after exposed to ultraviolet light weathering are also important. Fragility and cracking can be fully visible at naked eye, but tensile properties testing and deformation testing according to EN14809, done after this weathering test may be needed to identify any existing damage impacting these properties.

Any new Polysoft system is tested with an exposure that is equivalent to 7 years in a tropical environment without showing any sign of colour change or deterioration of physical appearance.

It is not a coincidence that the greatest success and highest market share of these Polysoft systems was achieved in the regions with the toughest environmental conditions with high UV radiation levels and extreme temperatures as Middle East and Australia.

Some materials may have a cheaper initial purchase cost, but may also have a shorter lifespan, hence it becomes more expensive over time.

View More Blog

-

What Are The Top 7 Benefits Of Using Soft-Fall Playground Flooring

-

Top 5 Types Of Slip-Resistant Flooring That You Need Today

-

Why Is Uv-Resistant Soft Flooring A Must-Have For The Outdoors

-

How To Cool Urban Heat Islands: Surface Choices Make A Difference

-

Global warming and the safety surfacing of Outdoor Playground, Fitness areas and Waterparks

-

The flooring of a Savannah Splash Zoo

-

Accessibility of Polysoft absorbent flooring in playgrounds, water parks, exercise areas and leisure spaces

-

Measuring slip resistance of a flooring system on dry and wet. The Polysoft choice and results

-

The colours on the flooring and fashion.